Do-it-yourself flushing of engine injectors is not such an easy task at first glance. Fuel system, while on car engine, is constantly exposed to harmful influences and polluted by various particles, plus, various deposits accumulate on it. The basis of these deposits is chemical compounds and particles (for example, sulfur) found in automotive fuel. The injection nozzles are considered the most vulnerable. During the use of low-quality fuel, the situation deteriorates many times, and the nozzles have to be changed or cleaned.

How dirty injectors work

- If the nozzles are dirty, the specific power of the car engine decreases.

- Further, detonation pops occur during acceleration of the car,

- On the Idling engine operation becomes more unstable, engine starting becomes worse over time and fuel consumption increases.

- The danger of exhaust also increases.

All this is determined by passing the test and diagnostics of the car.

In the event that the test revealed that the main cause of the breakdown is the nozzles, they must be replaced or washed. Flushing of such systems can occur both without removing the engine, and with a complete disassembly, i.e., the procedure for dismantling the engine is carried out. In fact, washing nozzles without dismantling the engine is much more inconvenient than vice versa, but sometimes this method is the only suitable one.

In the process of dismantling the nozzles, it happens that the seals are also replaced together with the ramp. This is a rather difficult and lengthy procedure.

When to change injectors

Often, we are surprised when a car service worker declares that our car “like air” needs flushing of the nozzles. Many drivers perceive these words as a desire to “pump out” extra money, since the user manual indicates the frequency when the injector should be cleaned. Indeed, the manufacturer indicated the mileage, at the end of which it is necessary (though not necessarily) to clean the injector. But the manufacturer did not take into account all the details. This calculation is carried out, mainly, on the standards of European fuel, and we fill in our cars with no one knows what. And the entire injection system in our car suffers from this, to be more precise - the nozzles in the injector.

How to clean nozzles with additives

Nozzle cleaning can be done different ways and each of these methods has its advantages and disadvantages. The simplest is to add a detergent additive to the car's gas tank. Similar additives are produced by almost all manufacturers of auto cosmetics. To flush the entire system, it is best to use a nozzle cleaner. One bottle of this liquid with a volume of half a liter is enough for 50-70 liters of fuel.

"Washing" in this way is subjected to all parts in the fuel system of the car. This also includes the fuel tank, the mechanism for adjusting the pressure, the fuel pump and, of course, the injectors.

It is important to consider that this method is quite risky, since all deposits and dirt that have been washed out of the fuel tank and gas line can further damage the pressure regulator valve. For this reason, flushing nozzles with additives may only be advisable as a preventive measure.

Another reliable method for flushing nozzles is flushing using special solvent supply units. Flushing occurs when the engine is turned on and it is running on a washing solvent. This method is quite effective and the result of washing is assessed as positive in most cases.

When flushing injectors with solvents, spark plugs can break. Therefore, flushing must be combined with the replacement of candles.

Among other things, the nozzle can also be flushed using high-performance fluids that pass through the nozzle. This method is carried out using special installations that imitate the action of the nozzle with the replacement of fuel with a special solvent. Also, an effective way to wash the nozzle is an ultrasonic bath. This method can be safely called the most stable.

It should be remembered that while using good European fuel, there is no need to clean the nozzles, but car manufacturers still recommend constantly changing these parts after the car has traveled more than one hundred thousand kilometers. If you use Russian gasoline, in this case, the need to clean the nozzles may appear after 15-30 thousand kilometers, but the stations Maintenance recommend cleaning after 20-40 thousand kilometers.

Cleaning nozzles on the stand

Ideally, the nozzle arrangement makes it possible not to clean the injector at all if the car is operated on high standard gasoline. But, as mentioned earlier, the realities of our existence are such that cleaning the nozzles in the injector has to be done much earlier. It is important to understand that most often the nozzles become clogged in winter, when the volatility of the fuel decreases. The first problems appear in the car.

How to clean the nozzles with your own hands

Don't stop at folk ways nozzle cleaning. True, there are different opinions on this matter. Some cannot get enough of the injector with the additives used. Some say that they add some amount of kerosene to the tank and do not know any problems. The real therapy is to use the fuel additives listed above. The frequency of their use is about three thousand kilometers.

How to clean the injector yourself

In the common people, this technique is called "enema". For high-quality flushing of the injector, we need:

- good quality flushing fluid;

- new candles included;

- 4-5 liters of normally refilled gasoline;

- syringe;

- assistant - press the gas pedal.

Sequencing

Mix flushing fluid and gasoline. Raise the hood and find the hose that goes from the "vacuum" to the intake manifold. Remove the adapter - it looks like a rubber tube.

Draw a mixture of gasoline and flushing liquid into the syringe, pour into the tube under pressure. Wait for 10-15 minutes. During this time, everything that the liquid has got on will oxidize.

Now we connect the assistant. He starts the car, which is rather difficult, since the tube is disconnected. The engine does not keep speed, stalls, you have to constantly press on the gas, maintaining a level of 2500-2800 Rpm.

At the next stage, we again inject a mixture of gasoline with flushing fluid. This is not an easy task because of the pressure inside the tube, which draws the syringe inward. At this time, the silencer makes various sounds: from pops to a terrible roar. There may be clouds of white smoke or black soot falling out.

It is not necessary to pour in a lot of washing mixture at once. It is better not to spare time and dose.

After pouring the entire mixture, we turn off the engine. When it cools down, you need to unscrew the candles and replace them with new ones. This method does not flush the entire system, but this is the best alternative to a trip to the service.

STP SUPER CONCENTRATED FUEL INJECTOR CLEANER

DOSAGE: whole bottle - 364 ml.

Application features: pour before refueling to evenly distribute the additive in the fuel and achieve maximum efficiency.

Test result: the liquid showed very high washing abilities. Easily dissolved deposits and to a suspended state, but it is recommended to use it only if you are sure that the gas tank is absolutely clean, otherwise dirt can clog the intake screen in the gas pump and disable it.

The preparation washed off more than 80% of contaminants. During the subsequent washing with a special solution, the remaining deposits were removed. This aggressive flush may be recommended for low mileage applications. it best option how to flush the injector yourself with a drug of this type.

DOSAGE: 355 ml.

Application features: the drug is very cheap, because it is domestically produced.

Test result: more than 60% of contaminants were washed away, and heavy deposits also succumbed. Subsequent washing did not reveal the presence of indelible deposits.

Despite the low cost, excellent results are shown, and its use is limited only by the cleanliness of the tank.

Video

Flushing nozzles with a special liquid:

Far from all owners of injection cars, and especially novice drivers, will be able to wash the injectors and clean the nozzles on their own. But, before starting this procedure, it is necessary to figure out whether it is possible to effectively clean the injectors and flush the injector without the help of a car service, or still you can’t do without a trip to a service station. It depends on various factors, but most often self-cleaning of nozzles and injectors is not a global problem.

To perform this procedure on your own, you need some training, basic knowledge of the design and operation of your car, so that you do not make gross mistakes during maintenance. It is also necessary to have certain devices, chemicals and tools, consult with professionals, carefully study the manual for the car, for washing chemicals. Only then can work begin.

Injector cleaning has become very popular in recent years. An incentive to self service behind his own car was a high price for this type of work.

The desire to save money leads to different methods of cleaning the injector and injectors, as opposed to visiting car repair services. However, improper cleaning of the fuel system can lead to malfunctions of the injection system and the need to purchase new injectors, which cost a lot of money.

When to clean the nozzles

An injector in a car is a pressurized fuel injection system. This is a complex device, which, in addition to an electric fuel pump, includes pressure regulators, a control system, various sensors that measure the properties of fuel, intake manifold and other elements.

A serious disadvantage of the fuel injection system is its rapid clogging and loss of efficiency due to the use of poor quality fuel. In this case, the problem of cleaning the injectors arises.

Cleaning and flushing of the injector should be carried out with a mileage of more than 20 thousand km, depending on the fuel used and the features of the system design.

- Dirty candles.

- Starting the engine is more difficult than usual.

- Uneven engine idling.

- Smoky exhaust from muffler.

- The engine does not develop maximum power.

If we consider the reasons for the decrease in the efficiency of the engine, then there are a great many of them. Therefore, doubts often arise whether the injector is to blame for poor engine performance. With insufficient experience in these matters, it is recommended to visit a service station.

Chemical reagents for washing nozzles

To clean the injector, there are various flushing fluids that must be selected carefully, without saving on cheap fakes. In case of the wrong choice, you will have to purchase a new set of nozzles, and savings will become a thing of the past.

The most popular liquid for cleaning the injector was the imported brand Wynn's. It is considered powerful. Vince is well suited for heavy injector contamination, and soot has appeared in the combustion chamber and on the valves. Such a chemical reagent is recommended for use on older cars.

For new modern cars Vince is not recommended, or even prohibited. When using it in new cars, you will have to change spark plugs and make other unplanned expenses.

Imported Liquid Molly reagent saves candles, and there will be no need to change them. However, such a liquid is not suitable for cleaning carbon deposits on valves. The advantage of Liquid Molly is its universal use, and low effect on nozzles.

Flushing fluid Lavr is similar to the Vince fluid in terms of the nature of the action on the injection system. But it has a high cost, because of which it is little used by both beginners and professional craftsmen.

The automotive chemicals market offers a large number of brands of fluid for flushing the injection system. Therefore it is important to do right choice funds.

The most modern equipment for servicing the injection system of injection engines is a washing stand. It is factory made and is commonly used in service stations and car repair shops. The cost of such equipment is very high, and is hardly suitable for individual use.

It is possible to independently make a device for flushing the injector from improvised materials without removing the nozzles.

Materials for homemade fixture

- Rubber hose 2 meters long.

- Plastic bottle with a volume of two liters.

- Nipples for tubeless tires 2 pcs.

- Fluid pump with pressure gauge.

- Clamps for fixing the hose 4 pcs.

- Pieces of wires, terminals, etc.

A device made of such elements will turn out to be quite simple, but sometimes it works no worse than factory equipment. You can buy a ready-made device or ask friends. After acquiring or making a simple device, you can start cleaning the injector.

Chemical cleaning of the injector

The methods of chemical cleaning of the fuel injection system include not only the use of the described fluids. For example, there are special additives added to the fuel. They partially remove carbon deposits from the valves and clean the nozzles. This is more like a preventive measure, and with serious contamination, it is not able to completely clean the system.

The procedure for dry cleaning nozzles without removing from the motor

- First you need to turn off the fuel pump. To do this, when the engine is running, you need to wait until it stalls. In this case, there will be no pressure in the fuel supply system, and you can start the main work.

- Then you need to connect the hose of the homemade device and secure it with a clamp with special care to avoid rupture during the cleaning procedure. The pressure in the fuel system can reach three atmospheres, this requires the careful execution of all stages.

- Close the return system. Otherwise, liquid with chemicals may enter the tank, which is not allowed.

- Pour the flushing liquid into the prepared container.

- Connect the liquid pump to the mains.

- Main stage. Before flushing the nozzle, make sure that all connections are secure and tight. Here you will need the help of a second person, who must turn on the liquid pump and increase the pressure to 3 atmospheres. We can assume that the cleaning procedure has begun. Depending on the amount of liquid used, cleaning the injector can take about 20 minutes. Vince liquid is sold in a 0.5 liter bottle, designed to flush the injector of one car. It is necessary to wait for the end of the liquid.

- External inspection is necessary to check the exhaust gases. If the cleaning is going well, then there should be no smoke at the end of the injector cleaning procedure.

- Replace spark plugs with a new set, if necessary.

- At the end of the flush, turn off homemade design and restore the integrity of the fuel system: connect all hoses, pump fuse, etc.

- Control the work power unit after cleaning. If the malfunctions that were before flushing are no longer visible, this means that everything went fine.

Professionals say that high-quality flushing of injectors makes it possible to significantly reduce fuel consumption. It can be considered more correct to bring fuel consumption to factory parameters. At the very least, the possibility of significant fuel savings is evident.

Self cleaning nozzles diesel engine produced in the same way as gasoline. For this, the device we have considered is suitable, and the procedure. But flushing diesel fuel equipment requires a more careful choice of chemicals and great care in cleaning.

Flushing the injectors after removing them from the engine

The injectors can also be flushed by removing them from the motor. There is a special spray for this, and the cleaning device is somewhat different from the one considered. With this method, you can also flush the injection system yourself, with great efficiency, but the whole procedure will be much more complicated and longer.

This will require the following materials:

- Two cans of carburetor cleaner.

- Electric bell button.

- Pieces of electrical wires.

- Car lamp 21 watts at 12 volts. Such lamps are installed in the direction indicators.

- Reel of PVC tape.

- The syringe is medical.

- Two terminals for connecting the injector.

The syringe can be sized to accommodate the O-ring nozzle inlet, typically a 2cc syringe.

The tube from the product in the can must be connected to the nozzle of the syringe, and wrapped with electrical tape.

Flushing order

- Release the pressure in the fuel rail, as discussed earlier, without warming up the engine.

- Disconnect the fuel return hose from the rail, and dismantle them.

- Disable electric wires from the nozzle and pull them out.

- Soak the nozzle nozzles for one hour in the cleaning liquid.

- Pull the plunger out of the syringe and insert the nozzle with the sealing ring.

- Connect one terminal of the injector directly to the negative terminal of the battery. And connect the other terminal in series with the button and the lamp to the positive terminal.

Connect the tube to the can, press the electric button and the valve. At the same time, cleaning liquid should be sprayed out of the sprayer. The flushing process should be continued until the liquid spray is finely dispersed, and the torch is a wide cone. After flushing the injectors, experts recommend changing the oil in the engine. Self-cleaning of the injector allows you to evaluate the results of your work, and draw the appropriate conclusions.

If self-rinsing and soaking do not give good result, this means that the dirt on the nozzles is very dense and cannot be cleaned by the chemical method on its own. In this case, an ultrasonic cleaning bath must be used.

This method of cleaning is quite expensive, and is used mainly in car workshops. The nozzles must be dismantled from the motor and placed in a special ultrasonic bath, in which they will be cleaned using the cavitation effect. The whole cleaning process consists of several stages. At the end of the first stage, the spray torch and the performance value are checked on a specialized stand.

Then another cleaning is carried out, then the next check. This will continue until the desired result is achieved. To determine the readiness of injectors for high-quality work, it is necessary to achieve a slight difference in their performance, which is no more than 3%.

After successful completion of the ultrasonic cleaning, the O-rings and filters should be replaced, if necessary. Ultrasonic injector cleaning has advantages and disadvantages compared to other fuel injection system cleaning methods.

The main advantage is the ability to remove serious contaminants. In such cases, chemical reagents are not able to cope.

But this method does not eliminate any contamination. Sometimes it is not possible to flush the nozzles. This often happens when water has entered the fuel tank, or the car has been standing for a long time. In this case, the car service center will probably offer to control the injectors on a special stand, which shows the possibility of further use of the injectors.

Often reviews about ultrasonic treatment are negative. There are reasons for this, when the masters incorrectly determined the method of cleaning the power system. Ultrasound may not be effective enough to clean the injector of an old car.

From exposure to ultrasound, new nozzles can become unusable and collapse. The quality of ultrasonic cleaning depends on many factors: the choice of modern equipment, the liquid to fill in the ultrasonic container.

The main criterion for high-quality cleaning is still the human factor. The professionalism of car service workers, as well as their accurate work, will ensure the quality of cleaning nozzles using ultrasound.

Understanding the procedure for flushing the fuel injection system at a qualitative level is not at all difficult if the conversation is technical. To pick up all the elements for adaptation, assemble the device and apply it most often does not cause problems. These works are carried out simply, especially by those people who know how to apply simple tools from the car kit.

Much harder to choose chemical agent for washing, especially since this procedure is more responsible. If you choose the wrong fluid, you can simply ruin the nozzles, and you will have to purchase a new kit, spend extra money. But even here you can not make mistakes.

Finding data on the flushing fluid used is not so difficult. There are specialized websites, fluid instructions and car manuals. If necessary, you can consult a master in a car service.

Experienced craftsmen advise using dry cleaning when there are no big problems with the engine during operation. And also there are no failures at idle, pollution is small. A low-contaminant flushing fluid will quickly get the job done and benefit the engine by removing carbon deposits from the valves.

Wet cleaning is considered more of a preventive measure than an effective flush.

For more complex problems with the car, and serious pollution, poor engine performance - start with a visit to the diagnostics. Here self-cleaning will not help. The service workshop specialists will check the system and determine the cause of the breakdown, ways to resolve the issue, including chemical or ultrasonic cleaning of the injector.

Most car owners with injection engines start to worry if the car behaves suspiciously. The first alarm bells - the engine shakes strangely at idle. Pops are heard, the tachometer needle can arbitrarily twitch up and down. Then it is felt that when driving, the car no longer accelerates so briskly, and the fuel from the tank seems to disappear. Many continue to drive and put up with the poor condition of the car. Worse, when the engine shakes so that the vibrations go through the car body. Such an error is hard to miss. But experienced motorists know that flushing the injector would quickly eliminate problems and bring the engine to a healthy state.

The cause of engine malfunctions is contamination of the fuel supply system. Dust, sand, water that enter the tank are easily retained by the fuel filter. But after replacing it, the situation may not change. Then we confidently diagnose the contamination of the injectors and the intake manifold.

When to flush an injector

How pollution occurs. First, resins settle on the engine parts, this is unburned fuel and its impurities. The precipitate then oxidizes and becomes a hard layer on the parts. If you refuse to clean the injection, then the problems in the operation of the motor will only increase: there will be high wear on the mechanisms, increased formation of coke and soot, the catalyst will experience excessive load, fail, etc.

Even a thin lacquer layer of 0.005 mm reduces the efficiency of injectors by 20% or more. The nature of the spray pattern changes: its shape and size. The nozzles lose their tightness, from which the injection control begins to malfunction. As a result, we see failures in idling and increased consumption fuel.

The quality of fuel, extreme weather conditions, long periods of stoppage in traffic jams make the process of pollution formation lightning fast.

You should know there are others possible problems: fuel filter, pump, fuel intake screen. These contaminated parts interfere normal operation engine. Prevention must be carried out every 20-30 thousand km.

You can clean the engine yourself. To do this, you will need special equipment and liquid for washing the injector nozzles. Choosing the right tool is easy. Today, the products of the Russian manufacturer LAVR and European products are popular on the market. Before choosing a drug, watch the video, how the compositions differ.

How to flush the injector with your own hands

Means for washing nozzles qualitatively remove deposits in the system. To carry out the procedure, a special pneumatic station is required. Such equipment can be freely purchased in Russia. Today there are pneumatic stations of domestic and Chinese production. If there is no need to constantly use such equipment, injector flushing can be done at car services that offer the service. The price for it will be from 1500 to 4000 rubles, depending on the car and the region of residence.

You can try to assemble the station yourself. That being said, you should be aware that flushing with makeshift stations is dangerous. Flushing liquids ignite more than fuel. Therefore, avoid fluid leakage. Hitting on an exhaust manifold a warm engine, the liquid will ignite instantly. Such a procedure can cost you not only a car, but life and health.

Necessary kit for flushing the injector:

- fuel hose (1.5 m);

- clamps (2 pieces);

- cylinder with a pressure gauge 1 l;

- hook for hanging the balloon;

- hose for shorting the line (to drown out the return line);

- adapters for connecting to the fuel rail;

- compressor;

- 1 liter of fluid for an engine up to 2 liters.

When the station is connected, the system looks like a hospital drip. Flushing nozzles does not require much experience. The main thing is to clearly follow the instructions for connecting and flushing. Here is a list of steps on how to mount the station for work.

Washing station installation

It is not necessary to change the oil and spark plugs after using the LAVR injector flush. So immediately start the engine and make a test run. On the first kilometers of the way, improvements in the operation of the motor will be felt.

How to choose a LAVR flush

LAVR offers two flushes for petrol engines and one for diesel engines.

In order not to wait for the symptoms of an engine malfunction to appear, plan a preventive maintenance every 20-30,000 km of run. We recommend flushing before winter season- for a confident start in cold weather, or in the spring - to increase power and dynamics.

The cost of cleaning nozzles in auto services is about 1,500 rubles, but you can clean them with your own hands.

To clean the nozzles with your own hands you will need:

Carburetor cleaner (about 2 cans);

brake hose;

Insulating tape;

Plastic clamps for electrical wiring;

A piece of 2-wire wire;

12 volt light bulb;

Knife (clerical or other)

The cost of all the above is about 300-400 rubles.

Nozzle cleaning process

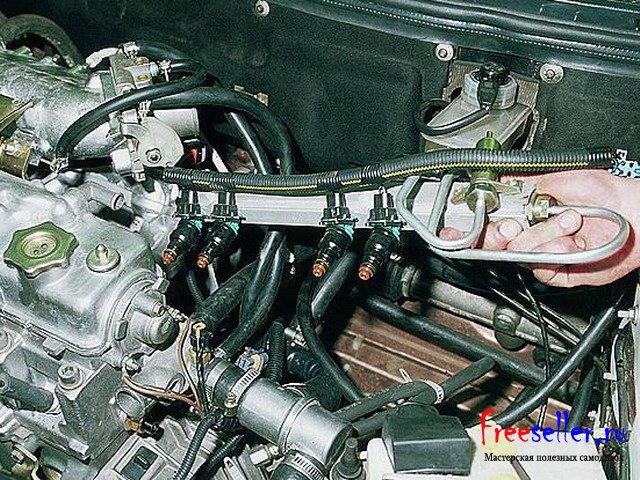

Removing the fuel rail to clean the injectors:

1. Disconnect the "negative" wire from battery.

2. Remove the rail with the fuel pressure regulator.

3. Disconnect the vacuum hose from the regulator.

4. Using two "17" wrenches, unscrew the fittings of the fuel pipes, releasing the fuel pressure.

5. Disconnect the ramp electrical connector.

6. Using a Phillips screwdriver, unscrew the screw of the fuel tube mounting bracket ... and remove it.

7. With a "5" hexagon, unscrew the two screws securing the ramp.

8. Pulling the ramp along the axis of the injectors, remove all four injectors from their seats and remove the ramp towards the left side of the vehicle.

Removing nozzles

1. Squeezing the spring clip, disconnect the electrical connector of the nozzle.

2. Using a screwdriver, move the nozzle retainer along the ramp ... and remove it.

3. Shaking the nozzle, we take it out of the ramp.

4. Prying off with a screwdriver with a thin sting, remove the sealing rings ... from the atomizer and nozzle body.

Making a homemade nozzle cleaner

1) We cut off a metal pressed nut from the rubber brake hose on 1 side.

2) We put the cut end of the hose on the nozzle, and fix it with a plastic clamp by tightening it.

3) At the other end of the hose we insert the tube included in the carburetor cleaner kit (if there is no such kit, we use a tube from WD-40 liquid). The remaining space between the tube and the brake hose can be filled with fum tape, unilok or use the remnants of soundproofing material. Then wrap tightly with electrical tape.

Rice. 1, 2,3. Homemade fixture for cleaning injectors.

4) The injectors are cleaned when a voltage of 12 V is applied to the injector, and in order not to burn the injector winding, we power the 12V bulb in series to the positive wire, make a break in the wire to ground by inserting a switch or crocodile clips, or using a working button, only then when you click on it. The whole circuit is connected to the battery.

Scheme of switching on the nozzle for cleaning.

1) We create pressure in the brake hose, for this we press the spray can several times.

2) We press the button, and apply voltage to the nozzle, the nozzle starts to spray.

3) Do not forget to press and hold the cleaner's sprayer to maintain pressure in the hose.

4) We clean the nozzle until the spray from the nozzle is uniform.

After cleaning the injectors, we assemble them back to the fuel rail, using new o-rings on all injectors from the side of the rail.

Install new sealing rings very carefully, without the use of any tool, after lubricating them engine oil or WD-40 fluid.

Install the injectors in the reverse order of removal, fixing them on the ramp with clamps, pre-squeezing them a little.

Reinstall the fuel rail, connect the fuel line, secure the ground terminal to the battery, turn the ignition key 3-4 times in the lock at 2-3 second intervals to pressurize the fuel rail, and check the tightness of the connection of the pipeline and injectors.

P.S. You should also change the fuel filter after cleaning the injectors, and preferably the fuel pump grid, and you should only refuel at proven gas stations, and preferably 95 gasoline.

Alexander Borisov, Samara

On most modern cars, an injector is installed as an injection system. The fuel system itself contains a number of different devices. In particular, nozzles are responsible for getting fuel into the cylinders. In fact, this is an element that passes through itself fuel mixture, it has a small opening and a needle valve. Various impurities that are contained in automotive fuel form a kind of plaque over time, which subsequently leads to clogging of the fuel system.

Signs of Injector Contamination

Sooner or later, every car owner faces the problem of a contaminated injector. After all, despite the fact that the node itself is quite reliable, nothing is eternal, and operation, as practice shows, is far from ideal laboratory conditions. Therefore, system pollution is a natural process that depends on a large number of factors. In particular, these are:

- The natural process of pollution. Even if the system will operate exclusively on clean and quality fuel, deposits will not be avoided, because gasoline contains many chemicals, including heavy components that settle on the walls of the elements.

- Poor quality fuel. Low-quality gasoline contains many times more impurities, sometimes there may even be water, fine sand, rust flakes, etc. Far from everything is eliminated fuel filter, and as a result, much settles on the walls of the nozzles, reducing their throughput.

- Other factors. Serious impact on fuel system can have a car age, and in particular mud deposits that heat up in fuel tank. A negative role is played by short trips on a cold engine or prolonged idling of the engine. This greatly speeds up the formation of deposits.

It is possible to determine that the nozzles require cleaning by the following signs:

- Increased fuel consumption. You may not notice this right away. deposits appear gradually, and, accordingly, the consumption will also increase far from immediately.

- There are problems with starting the engine, this can be especially noticeable in cold weather.

- At idle, the engine starts to work unstably, “troit”, the speed floats even on a warm engine.

- When the car is moving, failures appear, this is especially noticeable when driving intensively and pressing the gas pedal sharply.

- Decrease in acceleration speed, loss of power, detonation in the engine and characteristic pops in the exhaust system may appear.

- Contamination in the injectors affects the condition oxygen sensors and provoke them premature exit out of service.

- There are gaps when the mixture ignites in the cylinders, which subsequently provokes the breakdown of the spark plugs, high voltage wires, coils, etc.

How are nozzles cleaned?

It is possible to clean the nozzles both at a specialized service station and with your own hands. However, in the second case, some preparation and a basic set of special tools will be required. Consider the process of cleaning nozzles in more detail.

Washing preparations

Naturally, for the implementation of this procedure, specialized auto chemicals are actively produced, which can be conditionally divided into the following categories:

- Means that are intended for cleaning nozzles by direct contact. To use these fluids, the injectors will need to be removed from the engine.

- The so-called additives that are added to the fuel make it much easier to use such mixtures, because in fact there is no need to remove the nozzles, cleaning will be carried out directly during the operation of the car.

Thanks to the use of special tools, it becomes possible to achieve the following results:

- All nozzle channels are cleaned, and deposits accumulated in the cavities are removed.

- Significantly reduced fuel consumption and increased engine power.

Self cleaning equipment

In specialized workshops, a special stand is used to clean the nozzles. Of course, it is not advisable to purchase professional equipment for garage use. Therefore, motorists

Flushing tools

Flushing tools make equipment for washing nozzles from improvised means. In particular, you will need the following:

- Plastic two liter bottle

- Rubber hose about two meters long

- Two nipples from tubeless rubber

- Hose clamps, clamps and other little things

- Fluid pump with pressure gauge

Of course, the finished system turns out to be quite simple and even primitive, but in some cases it is not inferior in quality to professional equipment.

Step-by-step instructions for self-flushing

There are several very effective ways to clean nozzles, each of which has its own advantages and disadvantages. Let's consider each washing method in more detail.

Conclusion

The fuel system is one of the most important elements of the car, and for trouble-free operation vehicle you will need to carefully monitor the condition of the system and perform periodic preventive cleaning.