On cars of the Samara 2 series, the Volga Automobile Plant installed injection engines with electronic, distributed fuel injection. And for the VAZ 2114, which appeared in 2001, and was launched into the series in 2003, such a power plant was developed - model 2111. In subsequent years, various modifications of this machine were produced and other engine models were installed on some of them, such as - 21114, 11183, 21124 and 21126. But the most massive production cars were VAZ 2114 with engines of models 2111 and 11183.

Engine tuning theory

The concepts of "engine tuning" and "budget tuning" are incompatible, so I have almost nothing to say here. Of course, the most effective measure in tuning the motor is to increase the working volume. Only this gives a simultaneous increase in power, torque in the entire speed range - from a modified 1.8-liter VAZ-2112 engine, you can get a torque of more than 20 kg / m, and curb the maximum thrust of 10 kg / m of a standard 2110 engine already from 1500 rpm min! Another measure is the installation of various types of compressors, the replacement of fuel with a more "combustible" one (nitromethanol, i.e. alcohol), the supply of an additional fuel oxidizer (nitros), but this is expensive.And even the little that can be done with a reasonable investment requires the hands of a master and great experience. Therefore, I will dump here not only the motor itself, but also the power supply, ignition and exhaust system. timing- the gas distribution mechanism is the only place available to budget tuning where you can extract the "increase". Theory. The camshaft determines the valve lift (and the larger it is, the better - over the entire engine speed range), as well as the time and duration of the valves opening. Unfortunately, we cannot raise the valve as much as we want: the valve springs will choose the gaps between the coils and break. To raise the valve even higher, refinement of the cylinder head is required - first, lower the valve seats (for example, for MM54 - by 1 mm), then more radical measures - replacing springs, pushers, etc. - not budget. Therefore, for the motor 2108-2111, the maximum allowable valve lift is 9.7 mm, i.e. without alterations to the timing, you can put the camshaft "", "Nuzhdin" or their equivalent.

A few words about the time and duration of opening the valves - the width of the phases. The higher the engine speed, the earlier to the top dead center (TDC) you need to open the intake valve and close it later. This is necessary to provide a mixture that has a large inertia at high speeds, the ability to fill the cylinder as completely as possible and release the burnt charge. Accordingly, in the exhaust phase, it is also necessary to act ahead of time, so that by the time the hot mixture is reached, when the hot mixture is no longer doing work, let it start to leave the cylinder, and also keep the exhaust valve open after TDC in order to remove as much exhaust gases from the cylinder as possible . At low speeds, this leads to the fact that exhaust gases that have not yet completely escaped enter the intake system, not letting in a fresh mixture, which reduces traction on the bottoms, makes idling very unstable (therefore, on shafts with wide phases, it is necessary to increase the idle speed) . At high speeds, the overlapping of the intake and exhaust phases allows for a more continuous flow of gas through the CPG and, accordingly, burns more mixture and significantly increases the efficiency of the motor. The dependence is non-linear: a gradual increase in phase overlap first gives an increase in torque at high speeds, gradually shifting the maximum to ever higher speeds. After a certain moment, the subsequent increase in phase overlap has the opposite effect - a drop in power and torque even at high speeds. If we are talking about a two-shaft motor. then the task of the master is to find such a position of the shafts at which we will get the maximum torque at the maximum possible speed, and thus obtaining the maximum power. In the case of a single-shaft engine, you don’t need to think about it - the phase overlap is provided by the manufacturer, you just need to accurately set the position of the camshaft relative to the crankshaft, and the overlap can only be changed by changing the shaft.

To get "tractor" thrust, you need a shaft with minimal phase overlap and maximum valve lift. We will get more traction at low revs, which is very important for a city with eternal traffic jams.

The technical characteristics of the 1.6 liter engine do not differ much from previous versions. Compared to the one and a half liter, this engine has become more powerful by only 4 hp. Apparently, the designers of AvtoVAZ, in pursuit of increasing the engine resource, completely forgot that they would also need to add power. Therefore, happy car owners themselves are trying in every possible way to “add horses” under the hood. There are cases when the craftsmen managed to squeeze out up to 140 hp. from the VAZ 2114 engine, engine tuning added power almost twice as much as the factory specifications show. But as power increases, engine life decreases. Therefore, we will talk about how to increase power and at the same time reduce the life of the VAZ 2114 engine as little as possible.

List of works: Boring of saddles on the inner diameter, which is equivalent to increasing the valve;

List of works: Boring of saddles on the inner diameter, which is equivalent to increasing the valve;

A split gear appeared in the design;

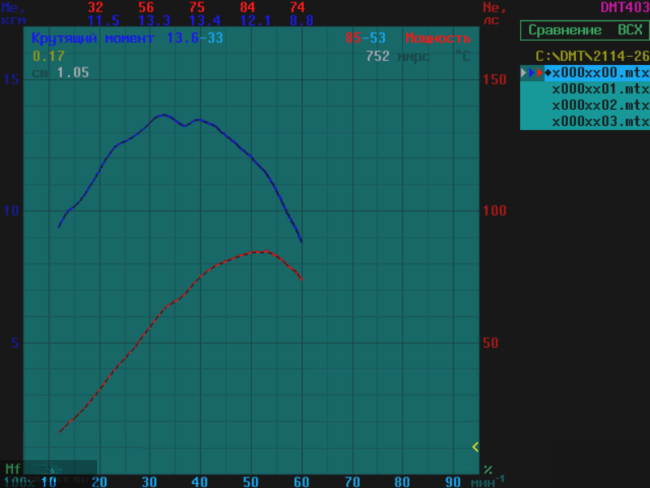

Valve crackers were replaced with imported ones just in case; A shaft with "narrow phases" was installed: outlet - 66 degrees, inlet - 70, opening angles - 246 and 250 degrees, respectively. The valve travel is 9.5 and 9.6 mm. Our new motor remained "not plug-in" - the valves do not reach the pistons. When checking on the stand (sensors were disabled), the result was not impressive.

If you install engineering firmware, you can choose the parameters "from and to". And then the picture looks better...

All sensors, including the lambda probe, were connected in the latter case. It was possible to remove 96 “forces” at 5300 rpm!

How not to increase the power of the VAZ 2114!

✔ Do not attempt to bore channels. This operation can be performed even in the absence of ball cutters, but in garage conditions nothing will work even with cutters. The bottom line is that the accuracy of the installation of the cutter is important - the error should not exceed 1-2 microns. ✔ As you can see, on the stock VAZ-2114 hatchback, the power increase was 24%, and this is without installing a “chandelier”, “improved exhaust” and other expensive elements. ✔ It makes no sense to buy a "racing cam" without having the right tuning firmware.How to make engine tuning VAZ 11183

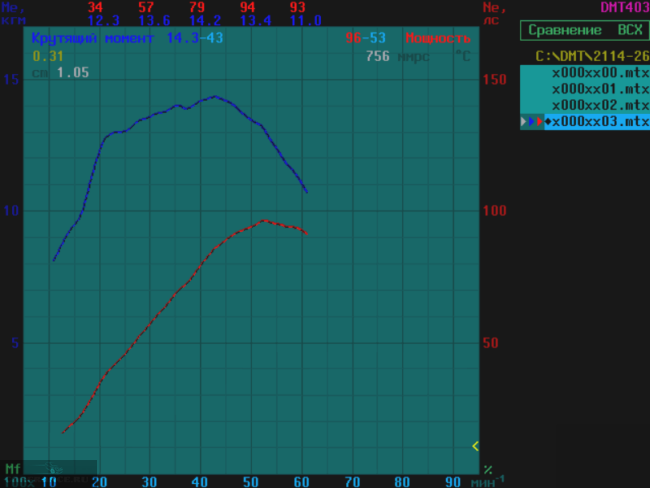

It is clear that the mandatory step in tuning the 11183 motor will be the replacement of the ECU. It's simple: the regular M74 unit cannot be flashed, but "January 7.2" is a good and time-tested solution. You will also have to abandon the “E-Gas” option, which means replacing the throttle assembly and receiver.

The intake tract details were borrowed from the 2111 engine. A “under the cable” pedal was installed, and the engine began to look human.

Everything works well with the January controller, but stock firmware is not an option if the camshaft has been replaced. And he, in turn, has the following parameters: Release phase width - 104; Inlet phase width - 109; Opening angle at the outlet - 272; Inlet opening angle - 268; Valve travel (exhaust / intake) - 9.5 / 10.1 mm. After installing a new shaft, the motor became "plug-in". However, on the 2114 hatchback, increasing power almost always comes with a trade-off. In this case, reliability had to be sacrificed. What's improved: Maximum torque increased by 14 Nm; Power also increased - the limit of "90 forces" was passed. By the way, any tuning leads to a decrease in durability. Make a choice.

Tuning 8 valve engine "split gear"

A split, that is, an adjustable gear, was not used in the last project. It is better to install it on “non-plug-in motors”. Setting method:1. The movable and fixed parts are marked with a label, the same as on a standard pulley; 2. Installation is carried out in the usual manner, setting the crankshaft and the timing mechanism according to the marks (as when replacing the belt), you should also remember the correct tightening torque of the belt; 3. If in the 4th cylinder the inlet and outlet valves are not open “to the maximum”, we carry out the adjustment: loosen the outer screws, and, holding the outer part of the gear, correctly set the camshaft. Tighten the fixing screws.

"Chandelier", that is, a zero-filter. The presence of such a filter for the engine is useful, but operation is fraught with difficulties: the fabric must be cleaned every 5-7 thousand km, and this requires "proprietary chemistry".

Throttle assembly of increased diameter (52 or 54 mm). It is difficult to think of a situation in which the 8-valve engine will not have enough air coming from the standard unit (d = 46 mm).

As for the exhaust path, you can install a “4-2-1 spider” - it creates a vacuum in front of the valve that has not yet been opened ... Torque and power are improved from this, the question is how much. Any "tuning" does not begin with the engine, but with the selection of "gear ratios" ... This advice is common, and it also applies to the VAZ-2108 and 2114 families.